Instrumentation

How Can We Help?

As the Kingdom advances to modernization where automation plays a critical role, INDUSTRIAL SYSTEMS GROUP (ISG) working as an approved local systems integrator with world renowned automation system leaders such as SIEMENS, HONEYWELL, EMERSON, ROCKWELL AUTOMATION, SCHNIEDER ELECTRIC, etc. the possibilities are endless. ISG provides full-fledged system, from Engineering Design to supplying front-end Instrumentation sensing devices up to the supervisory level SCADA Systems. ISG caters any industry applications. It could be as simple as a small agricultural farm or medium scale manufacturing plants, medical & pharmaceutical laboratories, food & beverage factories up to large scale industries such as SMART Cities, Industrial Oil & Gas Plants etc.

ISG shall continue to strive on becoming the Kingdom’s most trusted partner in realizing the Saudi Vision 2030 and will continue to play its part of building the Kingdom’s future by supplying systems which are proudly “Designed & Built Locally” – upholding excellence & integrity.

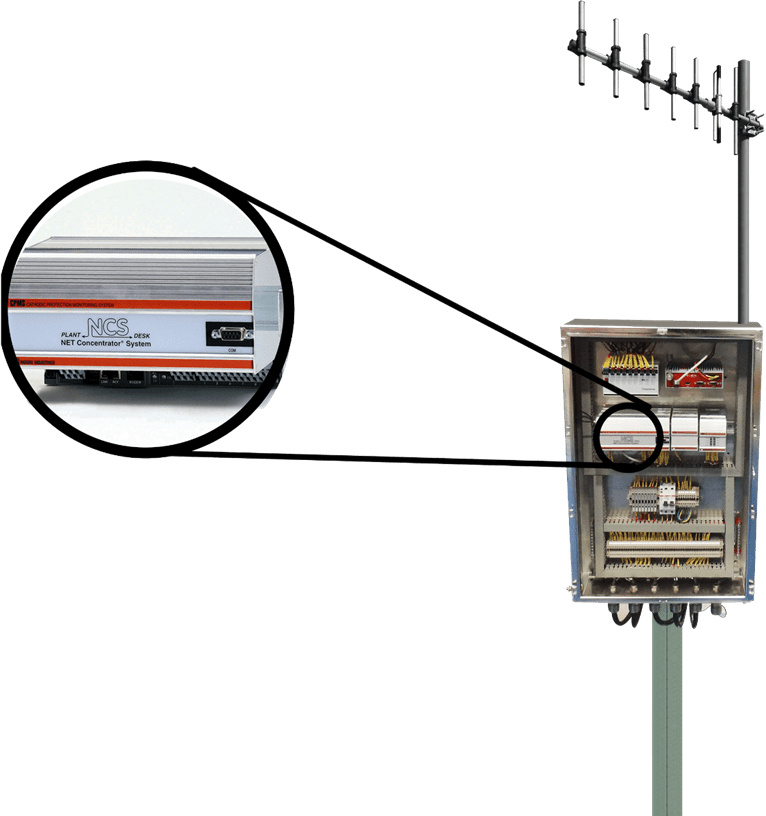

ISG locally designs & assembles WRMU for Cathodic Protection Applications. With a modular design approach, ISG builds a fully-functional system that is maintenance-friendly & future-proof design. This feat is achieved by the idea of using modular components manufactured by customer-approved vendors that is compatible with almost all industry standard open communication protocols. Leaving behind manufacturer proprietary standards limiting end-customers freedom to universal compatibility.

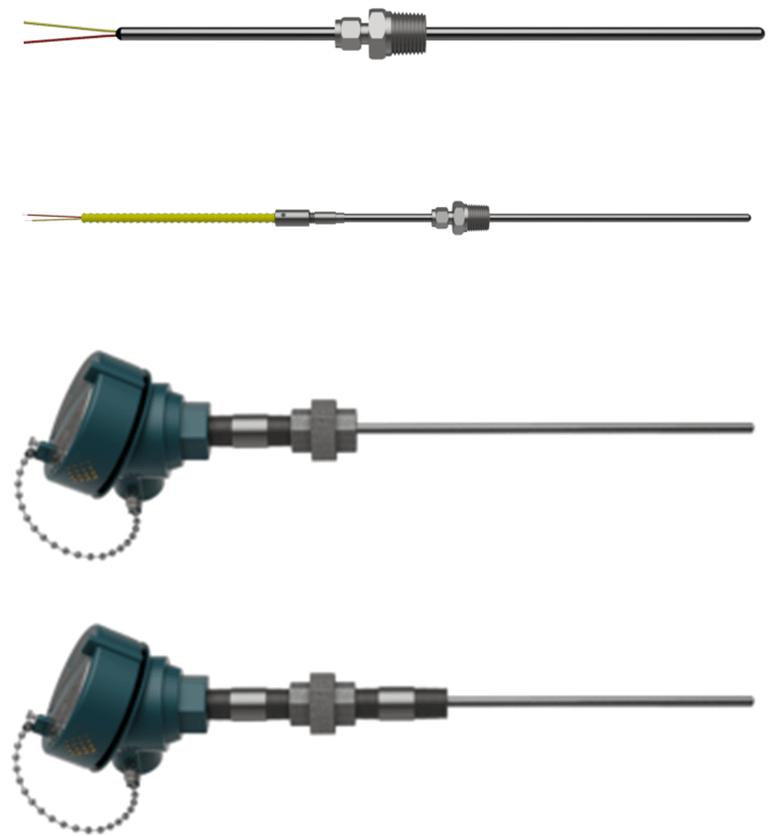

Every Thermocouple and Resistance Temperature Detector (RTD) that we manufacture is designed by global provider of temperature instrumentation, Daily Thermetrics. We understand that with thermocouples and RTDs, it is not the cost of the temperature sensor, but all the costs and time involved in replacing a sensor.

As the most critical part of the sensor assembly, each thermowell must be designed, manufactured, and tested properly to be able to seal against the process at the appropriate design pressure and temperature.

For hydrocarbon service, refiners around the world are increasingly specifying flanged thermowells with full penetration welds.

X-rays and Dye Penetrant Testing falls short of providing a complete volumetric inspection to verify the integrity of the weld. As such, we provide Ultrasonic Testing as a standard inspection procedure for 100% of all full penetration welds performed at our facility.